SAFETY FOOTWEAR

We have two manufacturing facilities with a clear focus of manufacturing safety shoes and shoe-uppers for our global clientele.

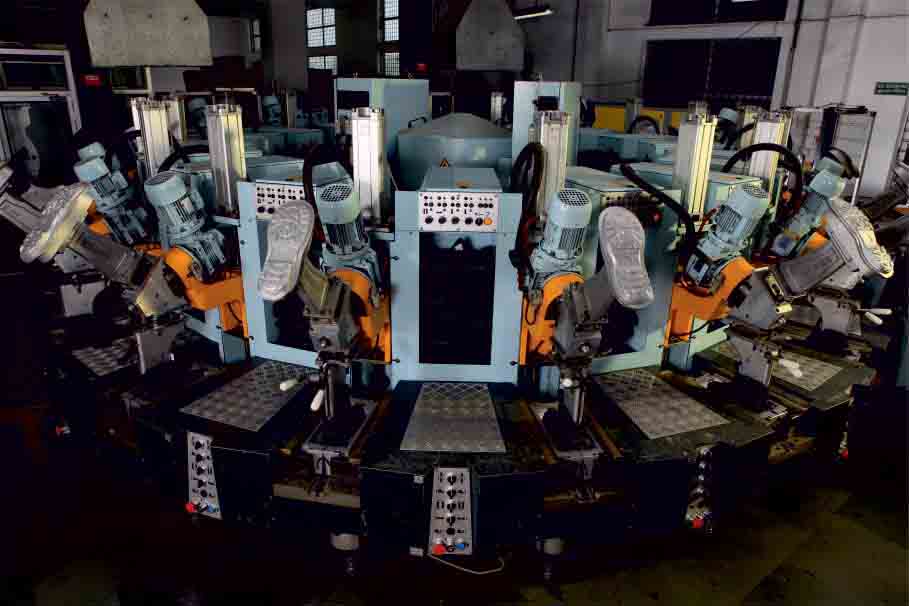

Our investments to create an infrastructure that can cater to the future needs of our customers, gives us the confidence to make commitments and deliver them. The units are equipped with modern-most machines and equally equipped workforce to handle them. A team of human resources consist of competent managers, designers and technically qualified, skilled and semi-skilled workers.

Company has PU injection machines with multiple stations making injected safety shoes on single and double density soles. The production capacity of the company for the shoes is 0.6 Million pairs per year.

Standards We Follow

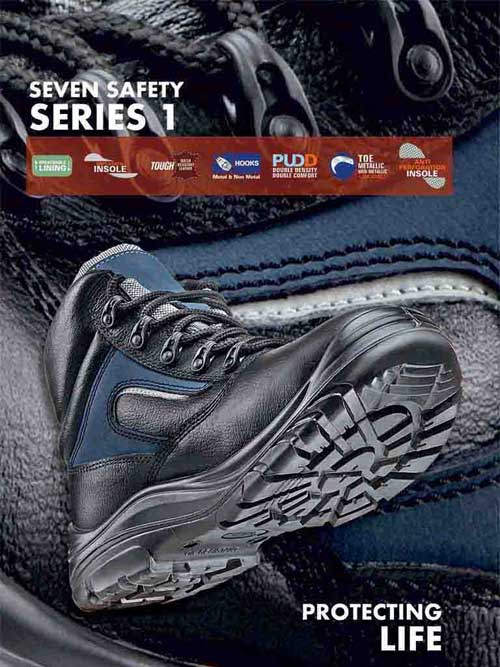

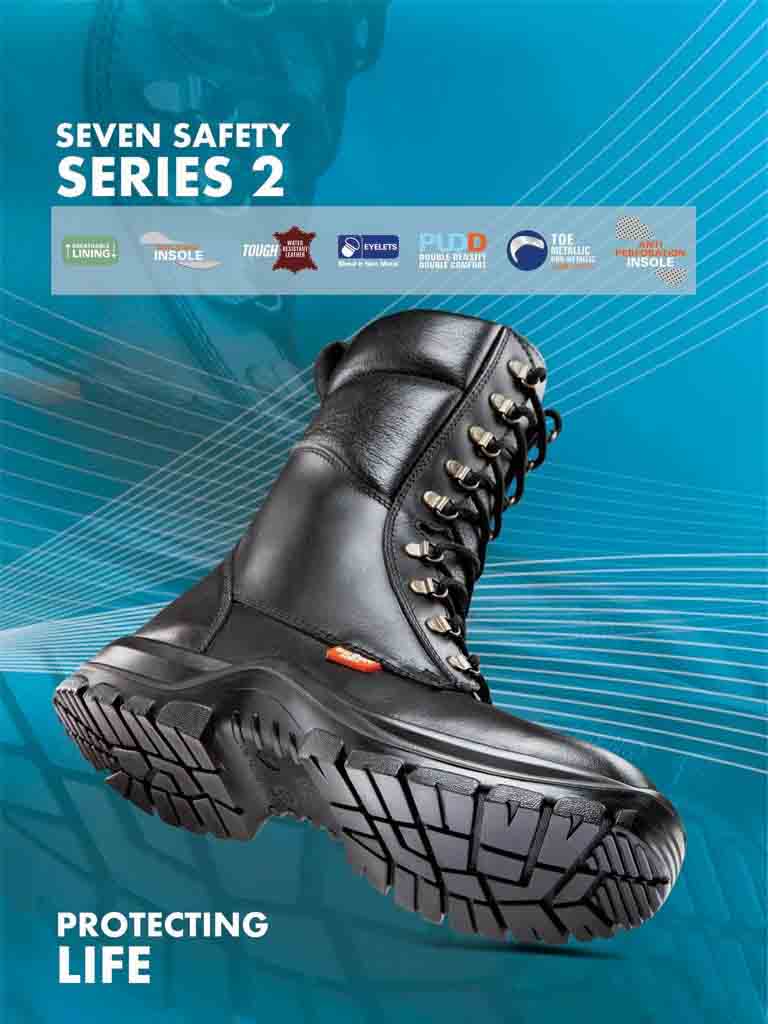

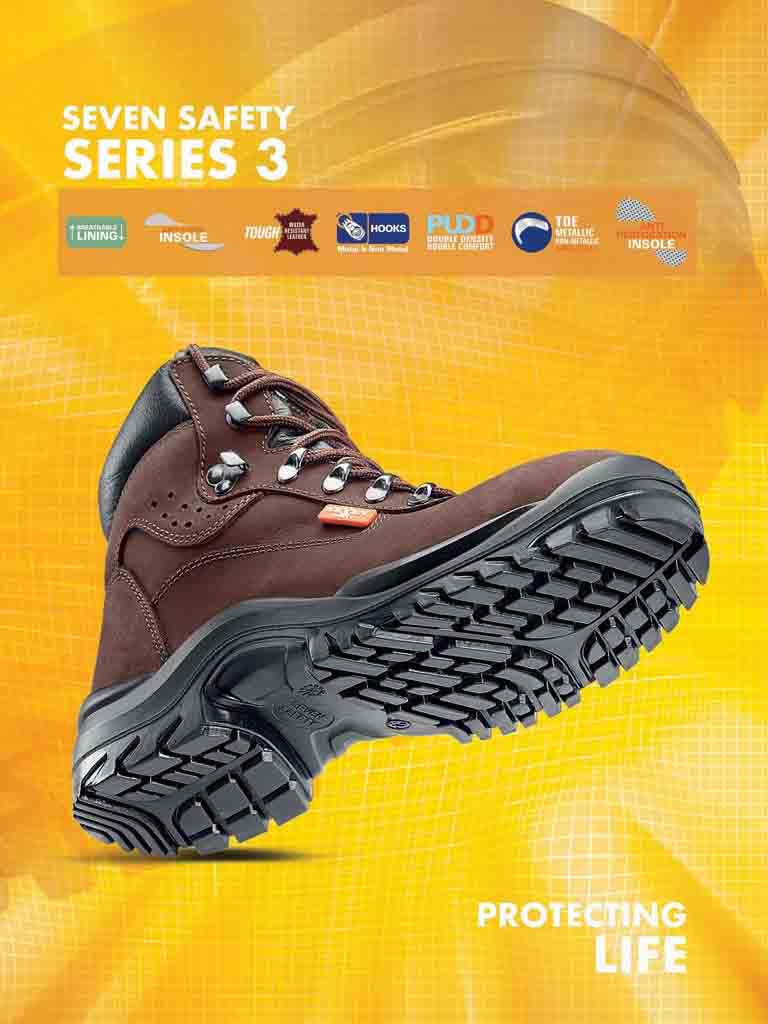

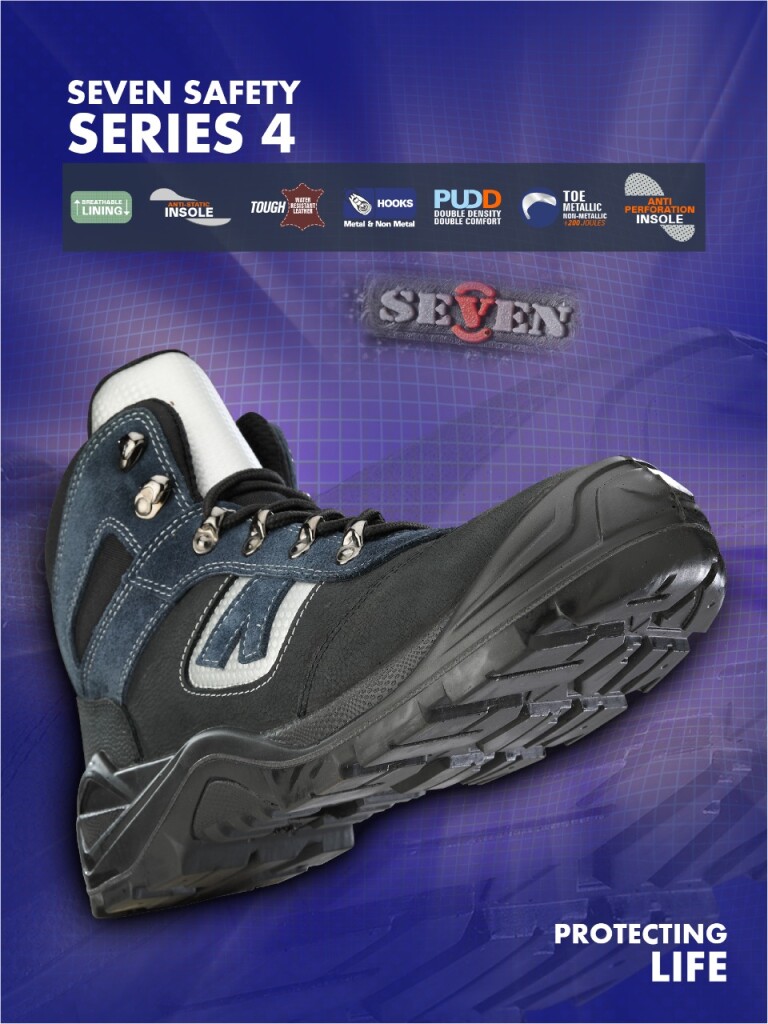

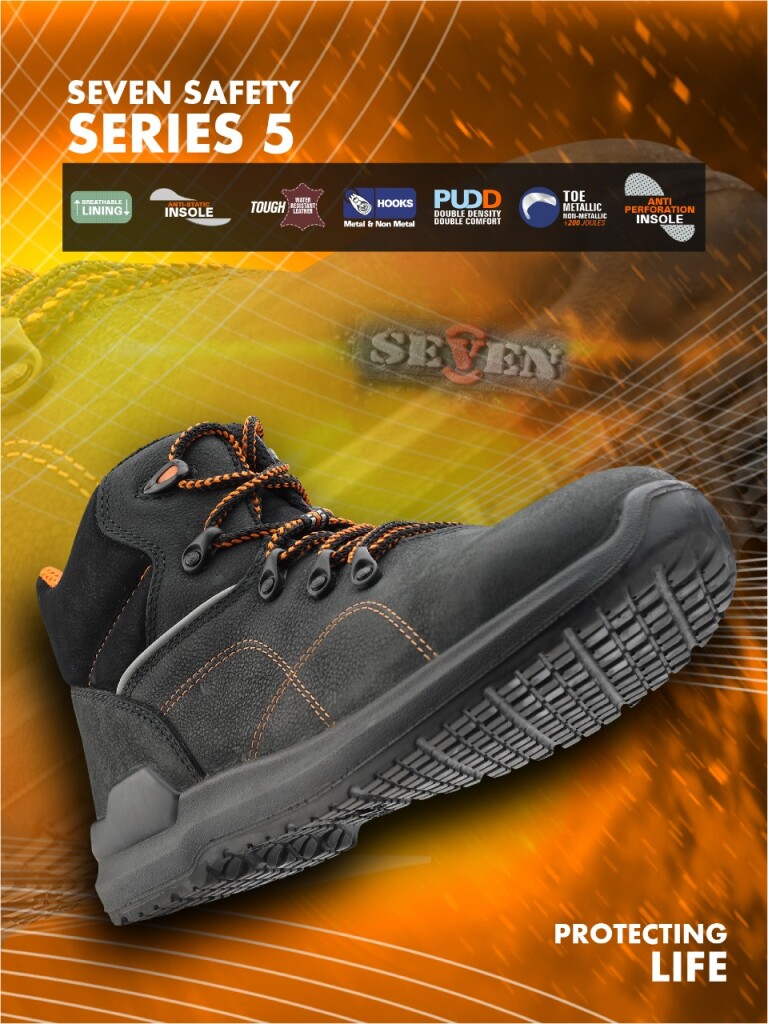

Safety Series

Better Protection

Tougher: Our in-house leather manufacturing units help us ensure the high quality of leather in use, which is tough and water resistant.

Anti-perforation: Use of anti-perforation insoles that provide protection from nail penetration and also makes the shoe lighter.

Metallic and Non-metallic toe caps: Use of both metallic and non-metallic caps. Non-metallic caps to provide equal toughness to the shoe, as metallic ones, yet making the shoe much lighter.

Anti-static: Use of anti-static sole and insoles dissipates the static charge and prevents accidents.

Anti-shock: The ESD technology used in the shoe makes it shock proof.

Higher Comfort Level